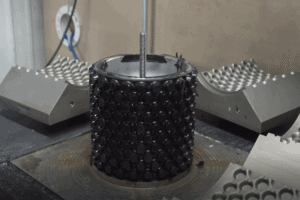

We machined and assembled the gear case and components for this sod cutter gearbox and delivered it to our customer in Johnson Creek, Wisconsin.

Using customer supplied specs and 2D cad drawings, we use CNC Turning (Chucking and Live Tooling Lathes) and Milling (Vertical and Horizontal) Machining Centers to machine components and the gear case casting to spec. Tires for this assembly are produced in house by molding and vulcanizing rubber to a wheel castings using our own custom molding equipment (built in house). Other components and hardware not produced in house are procured and supplied from outside vendors.

After manual assembly, the gearbox was transported to our custom painting facilities, and wet spray painted to client’s specs. This 30″ x 30″ x 23″ gearbox, made from steel, aluminum, and was dimensionally tested before and after assembly using Ductile Iron, Grey Iron, Alloy Steels and Powdered Metal, calipers, gauges, gauge pins, comparators, micrometers, custom test stands (CTS) and CMM. Tightest tolerances were within +.000″/-.001″, ±1ᵒ, and concentric within .002″ TIR.

Finally, the product was tested for functionality using a heavy duty chop box/gearbox test stand using repetitive cycling adjustment verification.