Our prototyping capabilities primarily focus on cast, forged, and sintered parts. However, we also maintain the resources needed to perform 3D printing if the project calls for it. Below, we provide an overview of our prototyping service offerings.

Our Prototyping Capabilities

- Cast components. Casting is a manufacturing process that involves pouring molten metal into a mold to create the desired part or product. It is ideal for materials like metal, resin, and certain types of rubber. Component designs can range from simple to highly complex.

- Forged components. Forging is a manufacturing process that involves imposing high pressures on a metal blank to form it into the desired shape and size. The components created are highly strong and durable.

- Sintered components. Sintering is a manufacturing process that involves using a combination of heat and pressure to compact and form fine powder made from metal, plastic, or ceramic into a solid structure according to the specs outlined in a digital 3D model. The components can be created in low to high volumes at a low cost per part.

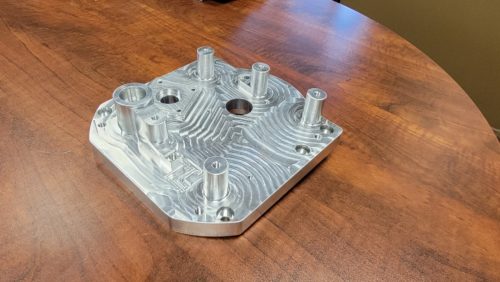

Since these processes generally have high entry and tooling costs, we often machine a version of the component from solid material first to test the design’s functionality. This procedure can mean significant tooling cost savings for the customer if the design is found not to work.

In addition to our prototyping capabilities for cast, forged, and sintering components, we offer 3D printing services. This process involves adding material layer by layer according to a digital model file to produce a complete component. It is commonly used for rapid prototyping services to produce parts and products faster than would be possible with most traditional manufacturing methods. Both plastics and metals can be used in 3D printing operations.

Advantages of Prototyping

Rapid prototyping services offer additional benefits to companies, such as:

- Faster production. Prototypes can be created in minutes or hours, depending on the product and production specifications.

- Easier design changes. The faster production speed of rapid prototyping operations enables multiple design iterations to be created, tested, and validated in the same period of time.

Prototyping Applications

Prototypes can be used for a variety of purposes. For example:

- They can be utilized as concept models, which allow designers to explore product ideas, demonstrate their validity to stakeholders, and create communications about them.

- They can be employed as functional models, which enable designers and developers to verify the functionality and manufacturability of a design before moving to the next stage.

- They can be used as cost-validation units, which demonstrate whether a design is economically feasible to manufacture.

Prototyping Services From Chapter 2 Incorporated

As a full-service manufacturer, Chapter 2 Incorporated has what it takes to bring a project from initial concept to prototyping to full production. Our 100,000 sq. ft. facility is fully equipped with the machines and tooling needed to produce prototypes units of cast, forged, and sintered components. To learn more about our prototyping capabilities, contact us today. To work with us on your next project, request a quote.