Bringing New Life to Legacy Equipment

Chapter 2 Transforms Critical Production Machinery Through Strategic Retrofit

In today’s manufacturing landscape, companies face a critical decision when legacy equipment begins to fail: invest in expensive new machinery or find innovative ways to modernize existing assets. For one air filtration manufacturer, this challenge became urgent when their custom filter press—a one-of-a-kind machine critical to production—became non-functional due to obsolete components and incompatible safety systems.

This is where Chapter 2, Inc.’s mechanical engineering and industrial automation expertise proved essential. Through a comprehensive 14-week retrofit project, the team not only restored functionality but improved the machine’s performance, safety, and user experience to modern standards—all while staying within budget.

The Project Challenge

Nick Ignarski, Chapter 2’s Project and Applications Engineer, explained during the interview: “These machines are one of one—there’s no other like it in the world that exists. They have the only ones.” The filter press, originally developed in the 1990s, had become a liability that could no longer be overlooked.

Eric Hoeft, Maintenance Team Lead, detailed the critical failure point: “When stopping the machine under load the voltage would spike and cause the drives to power surge, resulting in repeated failure and ultimately causing drive failures.” This wasn’t just a maintenance headache—it was a production bottleneck threatening the entire operation.

The customers’ requirements consisted of:

- Restore full functionality to a completely non-operational machine

- Achieve cycle times of 5.5 seconds or less

- Standardized controls across the machine

- Improve operator interface and troubleshooting capabilities

- Upgrade to current ANSI/OSHA safety standards

Chapter 2’s Strategic Approach

Chapter 2’s methodology reflects the same systematic approach it take towards any project within its organization

- Initial Design and Assessment

- Kickoff Meeting and Stakeholder Alignment

- Design Approval Process

- Component Sourcing and Programming

- Internal Testing and Validation

- Customer Runoff and Training

The Power of In-House Integration

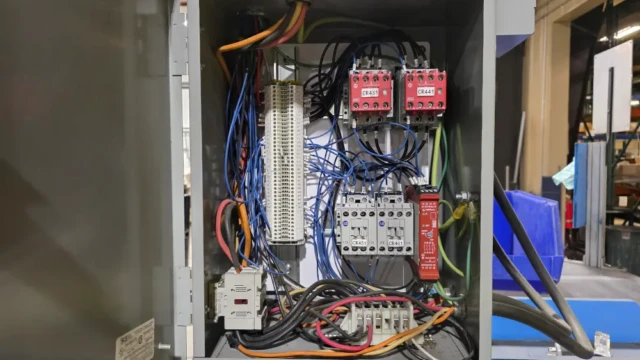

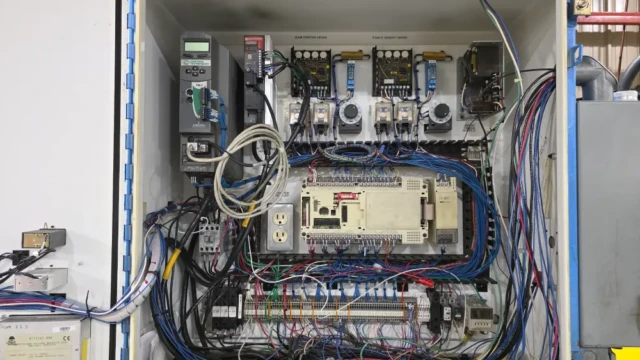

What sets Chapter 2 apart is their comprehensive in-house capabilities. “Everything was done in-house,” Ignarski emphasized. The project leveraged multiple departments:

Created custom components such as motor adapters

Developed complete electrical, mechanical and pneumatic design and drawings.

Refinished the machine frame and guarding for a cohesive appearance

Handled electronic upgrades and programming

This integrated approach eliminated the coordination challenges and delays often associated with multi-vendor projects.

Technology Standardization

One of the project’s most significant decisions involved standardizing on Rockwell Automation Allen-Bradley components. Hoeft explained the customer’s perspective: “Their shop is primarily sourcing towards Rockwell Automation. All the younger and newer employees are more familiar with that, and the technical colleges are promoting this software for students.”

This wasn’t just about brand preference. The standardization strategy delivered multiple benefits:

- Simplified maintenance and troubleshooting

- Reduced spare parts inventory

- Consistent operator training across equipment

- Easier software version management

Measurable Outcomes That Matter

The retrofit’s success can be measured in concrete improvements that directly impact production efficiency and operational excellence:

The upgrade from a 5-inch to a 15-inch HMI screen transformed operator interaction. “Instead of having 15+ manual toggle switches on there, everything would be displayed on the HMI.” Hoeft noted. “Someone could navigate the screens smoother… The buttons were bigger. Just a little bit more user-friendly overall.”

Implementation of a GuardLogix fully integrated PLC brought the machine up to current safety standards. “We were able to use a GuardLogix fully integrated PLC for them so that everything is very one route,” Hoeft explained. “They didn’t have to have multiple safety devices tied together to meet modern standards.”

Chapter 2 didn’t just fix the machine—they made it smarter. The team implemented background logic for maintenance diagnostics, created standardized screen layouts matching other facility equipment, and provided comprehensive documentation including:

- Electrical, pneumatic and mechanical drawings

- Preventative maintenance recommendations

- Safety assessment reports

- Recommended spare parts lists with lead times

- Cycle Time: Met the 5.5-second target

- Budget: Delivered under budget despite last-minute change orders

- Timeline: Completed within the 14-week schedule

- Functionality: 100% operational from completely non-functional state

Lessons for Modern Manufacturers

This project offers valuable insights for manufacturers facing similar challenges with aging equipment:

1. The Unknown Factor in Retrofitting

“I would say the only thing for us going in was just the unknown and working with what we had,” Ignarski reflected. “There wasn’t a ton of documentation on this machine from an electrical, mechanical or user interface standpoint.”

Key Takeaway: When retrofitting legacy equipment, expect documentation gaps and build flexibility into your timeline and approach.

2. Component Availability Challenges

“Allen-Bradley specifically, for a lot of these components, they’re not mass-produced,” Ignarski noted, citing lead times of one to two months on critical components.

Key Takeaway: Early component sourcing and maintaining a recommended spare parts inventory are essential for minimizing downtime.

3. The Value of Standardization

The decision to standardize on a single automation platform paid dividends in training efficiency, maintenance simplicity, and long-term supportability.

Key Takeaway: Consider facility-wide standardization when making retrofit decisions; the benefits extend far beyond the individual machine.

4. Future-Proofing Through Scalability

“We’d like to leave them a little room for growth,” Hoeft explained. “We try and leave at least 20% room in there so they can add future expansions or not just have a completely full electrical cabinet.”

Key Takeaway: Design retrofits with future expansion in mind to maximize the investment’s longevity.

5. Knowledge Transfer is Critical

Chapter 2 provided extensive training for both operators and maintenance staff, ensuring the customer could maintain independence while having support available when needed.

Key Takeaway: A successful retrofit includes comprehensive knowledge transfer to ensure sustainable operation.

The Future of Manufacturing: Retrofit vs. Replace

The economics are convincing. Rather than investing in new equipment that might cost hundreds of thousands, if not millions, manufacturers can modernize existing assets for a fraction of the cost while achieving:

- Modern control systems

- Improved efficiency

- Enhanced data collection capabilities

- Reduced maintenance costs

- Current safety compliance

The Sustainability Factor

Retrofitting aligns with growing sustainability initiatives in manufacturing. By extending the life of existing equipment, companies reduce waste, minimize their carbon footprint, and demonstrate fiscal responsibility—what Hoeft calls a “conservative approach” that’s “becoming more popular as companies strive to be more fiscally responsible.”

Looking Ahead

This successful retrofit project demonstrates that the future of manufacturing isn’t always about the newest equipment—it’s about making smart decisions that balance innovation with practicality. Chapter 2’s approach shows that with the right expertise, even the most challenging legacy equipment can be transformed into modern, efficient production assets.

The integration of intuitive operator interfaces, standardized control platforms advanced safety systems, represents just the beginning. As manufacturing continues to evolve toward Industry 4.0, these retrofitted machines can serve as bridges between legacy operations and future smart factory implementations.

For manufacturers facing similar challenges, the message is clear: before writing off that aging equipment, consider the retrofit option. With partners like Chapter 2 who bring comprehensive in-house capabilities, deep automation expertise, and a commitment to customer success, transformation is not just possible—it’s practical, profitable, and sustainable. Chapter 2, Inc. continues to lead in manufacturing innovation through its integrated approach to Manufacturing, Engineering and Technologies. For manufacturers seeking to modernize their operations through strategic retrofitting or custom automation solutions, review our industrial automation capabilities or contact us at 920-648-8125.