CNC Turning vs. CNC Milling

Machining is a type of subtractive manufacturing process that shapes materials into the desired product. Two main types of machining include CNC turning and CNC milling. During CNC turning, the cutting tool remains stationary while the material is rotated at a specific speed to create the exact shape. CNC milling, on the other hand, involves the workpiece being held in place while the cutting tool rotates around it.

Although these processes achieve similar results, they each offer their own unique benefits that make them suitable for different applications. Here, we’ll dive into the advantages and common uses of each method to help you determine which option is best for your needs.

CNC Turning vs. CNC Milling

While CNC milling and turning serve similar functions, they differ in terms of overall process, benefits, and applications.

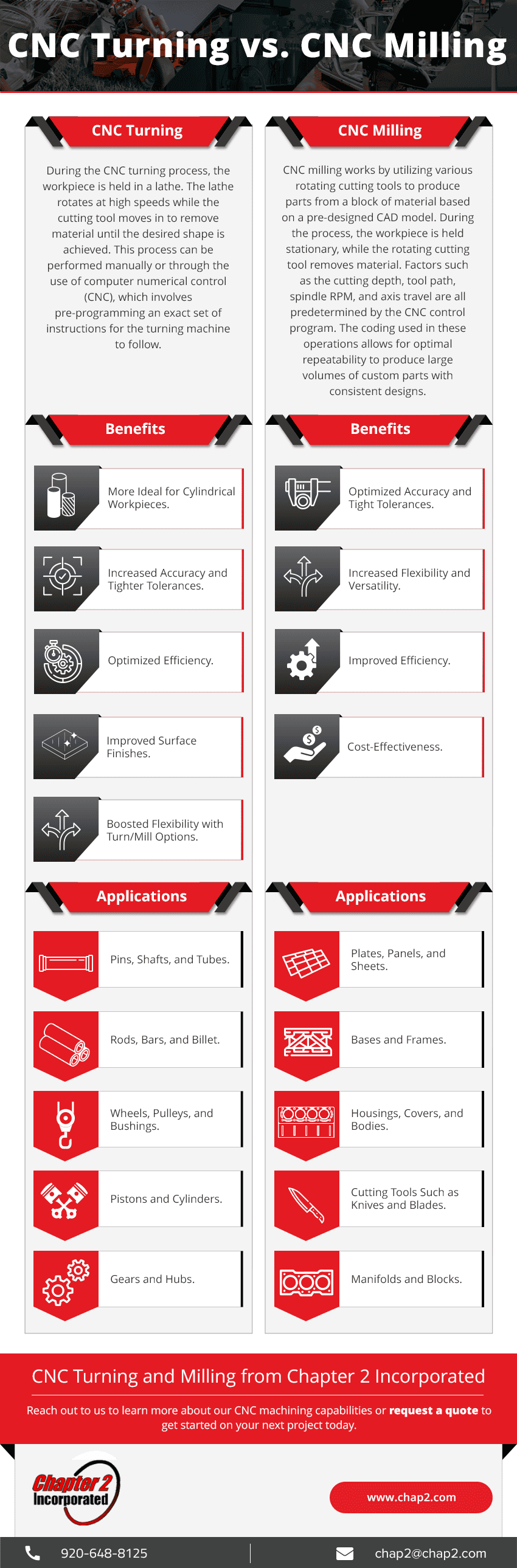

CNC Turning

During the CNC turning process, the workpiece is held in a lathe. The lathe rotates at high speeds while the cutting tool moves in to remove material until the desired shape is achieved. This process can be performed manually or through the use of computer numerical control (CNC), which involves pre-programming an exact set of instructions for the turning machine to follow.

CNC turning is particularly ideal for machining cylindrical parts, as they fit better into the lathe compared to other shapes. Milling is typically preferred for rectangular, square, and other angular geometries.

Benefits of CNC Turning

CNC turning comes with several key advantages over CNC milling, including:

- More Ideal for Cylindrical Workpieces. CNC turning is better at machining cylindrical parts compared to CNC milling.

- Increased Accuracy and Tighter Tolerances. Turning cylindrical parts allows for more accuracy and tighter tolerances when cutting the workpiece.

- Improved Surface Finishes. CNC turning can achieve higher-quality surface finishing when machining cylindrical shapes.

- Optimized Efficiency. Compared to CNC milling, CNC turning can machine cylindrical parts with enhanced efficiency. While you can still mill a cylindrical part, it may not be as accurate or efficient as turning it.

- Boosted Flexibility with Turn/Mill Options. CNC turning centers with some milling capabilities offer more flexibility. Having turn/mill options also eliminates the need to purchase a separate milling center, improving cost-effectiveness.

Applications of CNC Turning

CNC turning is well-suited for the following applications:

- Pins, Shafts, and Tubes

- Rods, Bars, and Billet

- Wheels, Pulleys, and Bushings

- Pistons and Cylinders

- Gears and Hubs

CNC Milling

CNC milling works by utilizing various rotating cutting tools to produce parts from a block of material based on a pre-designed CAD model. During the process, the workpiece is held stationary, while the rotating cutting tool removes material. Factors such as the cutting depth, tool path, spindle RPM, and axis travel are all predetermined by the CNC control program. The coding used in these operations allows for optimal repeatability to produce large volumes of custom parts with consistent designs.

Benefits of CNC Milling

The key benefits of CNC milling include:

- Optimized Accuracy and Tight Tolerances. CNC milling offers a high degree of precision for machined parts. This allows tight-tolerance components to be produced both easily and efficiently.

- Increased Flexibility and Versatility. CNC milling can work with parts of many sizes and shapes. Because the cutting tool can move along multiple axes, it can machine a workpiece on all sides.

- Improved Efficiency. CNC milling offers enhanced efficiency when working with square, rectangular, and other angular workpieces.

- Cost-Effectiveness. Due to the accuracy of CNC milling, it significantly reduces errors during the machining process and eliminates unnecessary waste.

Applications of CNC Milling

CNC milling is mostly well-suited for workpieces that aren’t cylindrical, as they don’t need to fit into the turning center. Common applications include:

- Plates, Panels, and Sheets

- Bases and Frames

- Housings, Covers, and Bodies

- Cutting Tools Such as Knives and Blades

- Manifolds and Blocks

CNC Turning and Milling from Chapter 2 Incorporated

Understanding the key differences between CNC turning and CNC milling is key in selecting the method that best fits the needs of your project. If you require dependable turning or milling services for your application, the professionals at Chapter 2 Incorporated have the equipment and expertise needed to give you quality results every time. We offer turning and milling services for clients across a range of industries, including power generation, agriculture, industrial equipment, medical, and oil and gas.

Reach out to us to learn more about our CNC machining capabilities or request a quote to get started on your next project today.