Chapter 2, Inc. is an industry leader in production and precision machining, and combined with our assembly and sub-assembly services, we are a full-service option for companies looking to outsource product production. Our assembly process serves various industries with our knowledgeable team experienced in all types of material and assembly requirements.

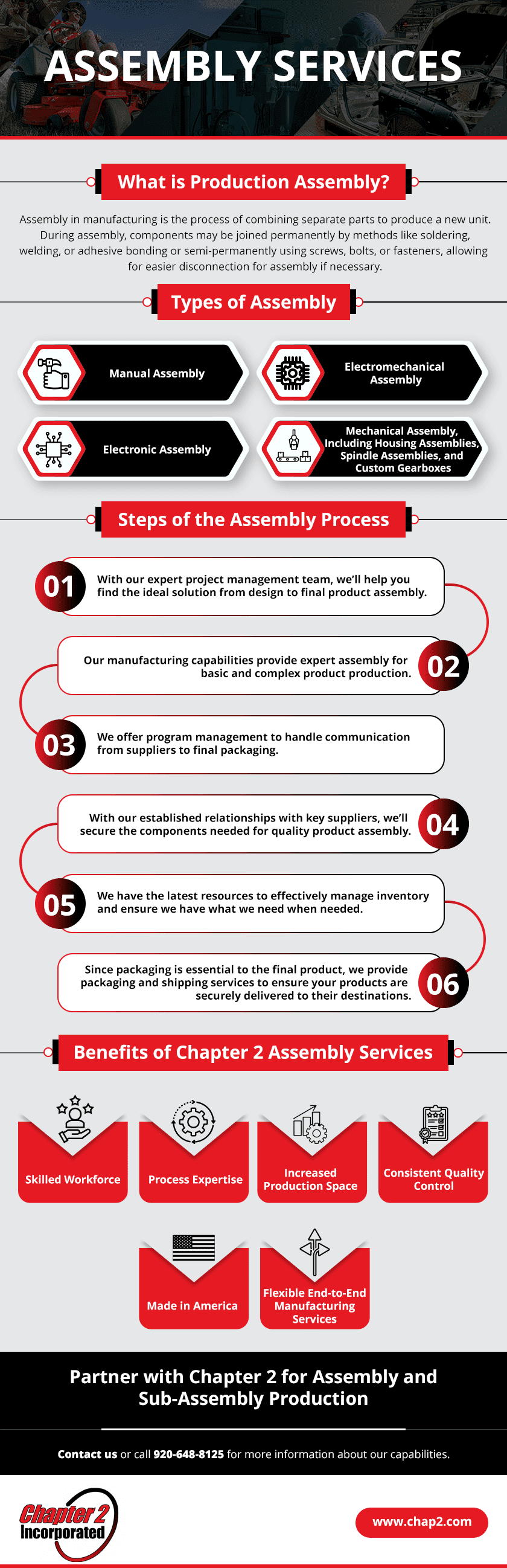

What is Production Assembly?

In modern manufacturing, many production companies specialize in specific parts of the production process. Because of this, several companies may be involved in producing parts of the same component or product at different stages of the process — from manufacturing to assembly to marketing. Assembly in manufacturing is the process of combining separate parts to produce a new unit. During assembly, components may be joined permanently by methods like soldering, welding, or adhesive bonding or semi-permanently using screws, bolts, or fasteners, allowing for easier disconnection for assembly if necessary.

Types of Assembly:

- Manual Assembly

- Electromechanical Assembly

- Electronic Assembly

- Mechanical Assembly, including housing assemblies, spindle assemblies, and custom gearboxes

The Production Assembly Process

In the simplest terms, assembly refers to taking components and parts and joining them into a final product through a series of steps. The production assembly process may include various manufacturing methods, such as welding or other fabrication techniques. Fabrication steps can consist of manual or automated processes for the product’s final assembly.

Steps of the Assembly Process

From start to finish, Chapter 2’s assembly services provide everything needed for your product’s production. We handle all steps of the production assembly process to allow you to focus on other critical aspects of your business.

- With our expert project management team, we’ll help you find the ideal solution from design to final product assembly.

- Our manufacturing capabilities provide expert assembly for basic and complex product production.

- We offer program management to handle communication from suppliers to final packaging.

- With our established relationships with key suppliers, we’ll secure the components needed for quality product assembly.

- We have the latest resources to effectively manage inventory and ensure we have what we need when needed.

- Since packaging is essential to the final product, we provide packaging and shipping services to ensure your products are securely delivered to their destinations.

Advantages of Assembly

Assembly and sub-assembly services play an important role in the success of manufacturing production. While some OEMs can handle assembly and sub-assembly in-house, many outsource certain production operations to companies specializing in specific assembly areas.

Major advantages of contracting the assembly process include:

- Reduced production costs

- Increased process quality

- Decreased manufacturing times

- Increased assembly capacity

How to Choose the Best Service

Choosing the best assembly manufacturer ensures quality products and reliable services. Consider the following when selecting an assembly production partner:

- Assembly type needed: Companies specialize in different types of assembly, so it’s best to look for one with the area of expertise that suits your needs.

- Technology used in the facility: Assembly and sub-assembly production benefit from high technology integration, so look for companies with modernized processes.

- Complimentary services: Companies offering additional services, like storage, maintenance, and transportation, can help reduce costs and ensure industry compliance.

Chapter 2, Inc. has expertise in different industries and materials to handle a wide range of assembly and sub-assembly services to meet your unique needs.

Benefits of Chapter 2 Assembly Services

Chapter 2, Inc. specializes in assembly services. Therefore, there are many advantages to partnering with us for the assembly and sub-assembly of your products.

- Skilled Workforce: Our team of skilled and experienced technicians saves you from finding, hiring, and training new employees necessary for in-house assembly.

- Process Expertise: Specializing in assembly processes allows us to continually optimize the process to produce and deliver higher quality products faster and with less waste.

- Increased Production Space: When outsourcing your assembly or sub-assembly production, your company’s production footprint increases without requiring a capital-intensive investment.

- Consistent Quality Control: Our team follows stringent quality control procedures to ensure quality products that meet or exceed your requirements and industry standards.

- Made in America: We assemble and deliver your products from our Wisconsin-based facility.

- Flexible End-to-End Manufacturing Services: Outsourcing your assembly to a trusted USA-based manufacturer gives you the confidence of knowing your products will ship on time and will be finished with the quality expected by your customers.

Partner with Chapter 2 for Assembly and Sub-Assembly Production

With years of manufacturing experience, Chapter 2, Inc. provides quality assembly and sub-assembly services for many industries. We offer in-house manufacturing, fabrication, and finishing services using the latest equipment and technology. For quality assembly production solutions, request a quote today. Contact us or call 920-648-8125 for more information about our capabilities.