At Chapter 2 Incorporated, we understand that creating precision components is only possible if you utilize high-quality tooling. We’re a full-service contract manufacturer, and since our beginnings in 1973, tool and die development has been among our core competencies. Our experienced team will work closely with you to design and build custom tools and dies tailored to your needs.

So, what is tool and die machining? Learn more about our production capabilities at Chapter 2.

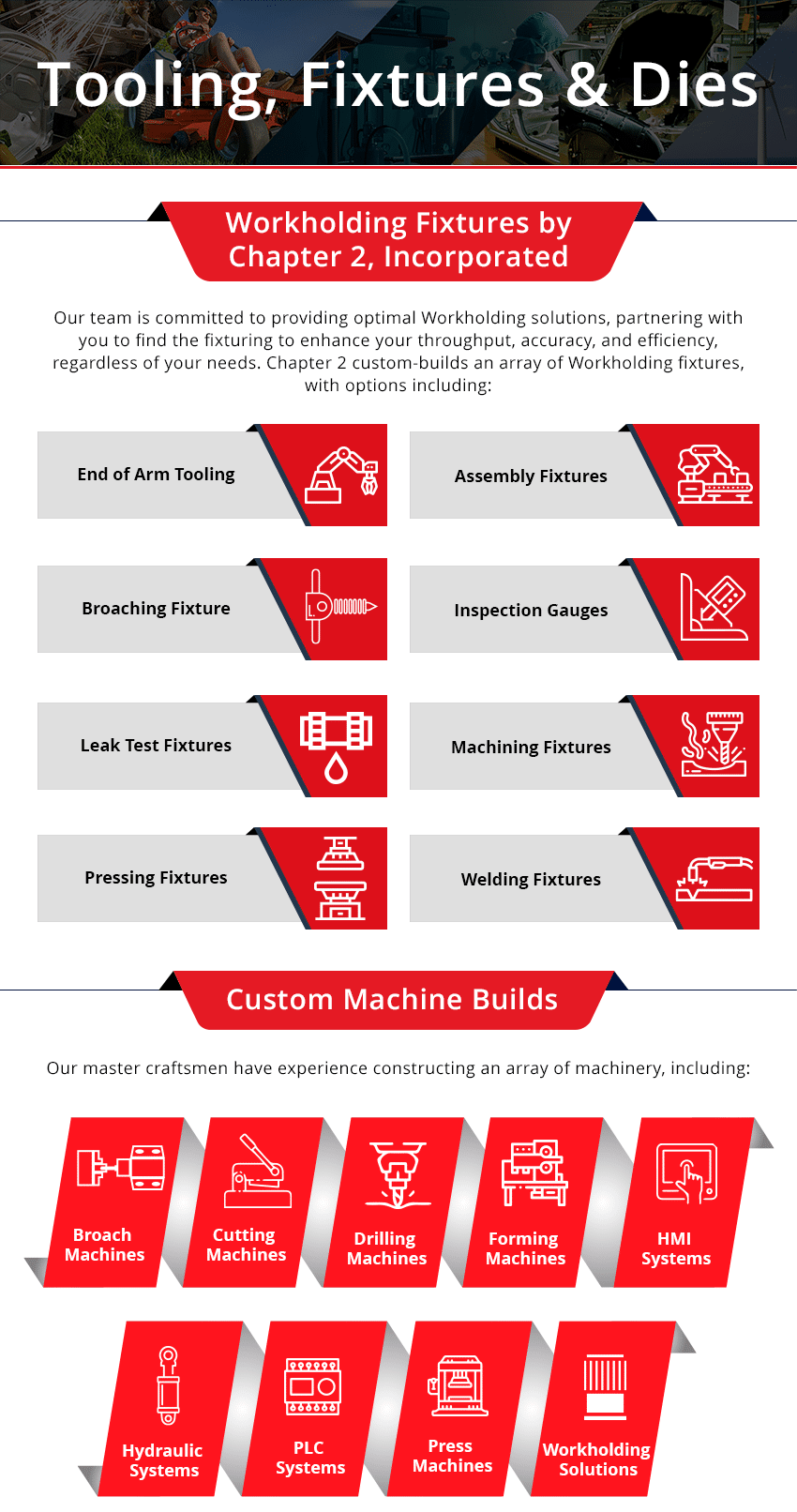

Workholding Fixtures by Chapter 2, Incorporated

Our team is committed to providing optimal Workholding solutions, partnering with you to find the fixturing to enhance your throughput, accuracy, and efficiency, regardless of your needs. Chapter 2 custom-builds an array of Workholding fixtures, with options including:

- End of Arm Tooling.

- Assembly Fixtures. These fixtures orient assembly components to facilitate the assembly process and shorten the time to product completion.

- Broaching Fixtures. Broaching fixtures keep a part secure so that, when a toothed tool is applied to it, machinists can remove material from the part without it shifting.

- Inspection Gauges. These gauges help ensure that a part meets customer specifications, measuring completed components or master parts for calibration.

- Leak Test Fixtures. Leak test fixtures hold a component in place during leak testing, which uses gas or liquid and pressure loss values to determine if a part is within its leak limit.

- Machining Fixtures. These fixtures securely hold workpieces in position using manual, hydraulic, or pneumatic clamps, better enabling machinists to create a precision component.

- Pressing Fixtures. Applicable for inserting press fit connectors, pressing fixtures support and align circuit boards.

- Welding Fixtures. Utilizing manual or pneumatic clamps, welding fixtures hold workpieces to allow for manual or robotic welding.

Our team has gained extensive experience in Workholding solutions over the last 50+ years, assisting clients in industries ranging from automotive, construction, and medical equipment to food packaging, agriculture, and lawn and garden. We operate a large, ISO 9001:2015-certified CNC machine shop along with a full-service fabrication and weld shop. With our Workholding knowledge, our dedicated team of highly skilled fixture technicians, and our machine shop and quality testing capabilities, we can help you address virtually any Workholding challenge you experience with an innovative solution. Documentation will ship with all our fixtures, and we have secure file transfer capabilities, as well.

Custom Machine Builds

At Chapter 2, we offer machine-building services using 2D AutoCAD and 3D SolidWorks modeling to provide customers with custom equipment solutions. Our talented technicians and engineers focus on the unique needs of each client in our machine builds, tailoring each piece of machinery to help streamline operations or address specific challenges. Our master craftsmen have experience constructing an array of machinery, including:

- Broach Machines

- Cutting Machines

- Drilling Machines

- Forming Machines

- HMI Systems

- Hydraulic Systems

- PLC Systems

- Press Machines

- Workholding Solutions

Our wealth of knowledge in diverse markets enables us to build machines for applications across industries. We’ll start with a detailed model, and make suggestions to help you optimize your machine build for enhanced efficiency or performance. Our capabilities extend to welding, repairs, machine rebuilding and retrofitting, reverse engineering, and control systems to best serve you.

One Stop Source for Tool and Dies Needs

Tool and die making involves manufacturing plastic molds, jigs, stamping dies, and fixtures. Without these components, production manufacturing at the rate of the modern age would not exist. At Chapter 2, we specialize in developing tools and dies for machining operations across numerous industries, including medical, food production, and auto manufacturing, to name just a few.

Are you wondering if we can produce the dies you need? Here’s a sampling of what we have to offer our industrial and manufacturing clients:

- Bending Dies

- Broaching Dies

- Cutting Dies

- Combination Dies

- Compound Dies

- Forming Dies

- Simple Dies

- Shearing Dies

- Trim Dies

- Transfer Dies

- Progressive Dies

Our breadth of service, experienced team members, and willingness to work with customers to achieve necessary results set us apart from our competitors. Custom order dies for your manufacturing facility for small or large production runs. You can count on our creative designers to deliver fine-quality tools and dies.

Our elements of success include:

- Focused customer service

- Efficient, cost-effective tools and dies

- Attention to detail for every customer on every job

- Talented designers and engineers who think outside the box

Communication and collaboration form the backbone of our interaction with clients. Partnering with us on your tool and die projects helps ensure that you get your fixture or die well before your first production run.

Chapter 2 Is a Knowledgeable Partner

Our valued customers choose Chapter 2 as their trusted partner in designing and developing custom tools and dies because we’re committed to providing excellent customer service, efficient machining processes, and a continued focus on quality. The benefits to you are as follows:

- Enhanced quality through systematic testing and quality control protocols

- Boosted productivity through standardized operations and strategic planning

- Decreased waste of worker and machinery time as well as material usage through heightened efficiency

- Lower costs due to less material waste, fewer inefficiencies, and continual manufacturing improvements

Chapter 2 handles everything from design to manufacturing to testing. Partner with us for modern equipment, dedicated testing labs, and experience in numerous industries, including medical and military applications.

Ensure durability and consistent quality with tools and dies produced by one of the top companies in the business. We’ve been doing this for 50 years, and we will continue serving our customers over the coming decades.

The right tools and dies can improve your throughput and accuracy when you team up with the right company for the job. Feel free to request a quote today or call us at 920-648-8125 with any questions you may have. Click here to read a case study.