At Chapter 2 Incorporated, we provide a broad selection of contract manufacturing services to accommodate a wide range of manufacturing needs. Regardless of the customer’s industry or application, our team is fully dedicated to providing quality products and services that meet and/or exceed their expectations.

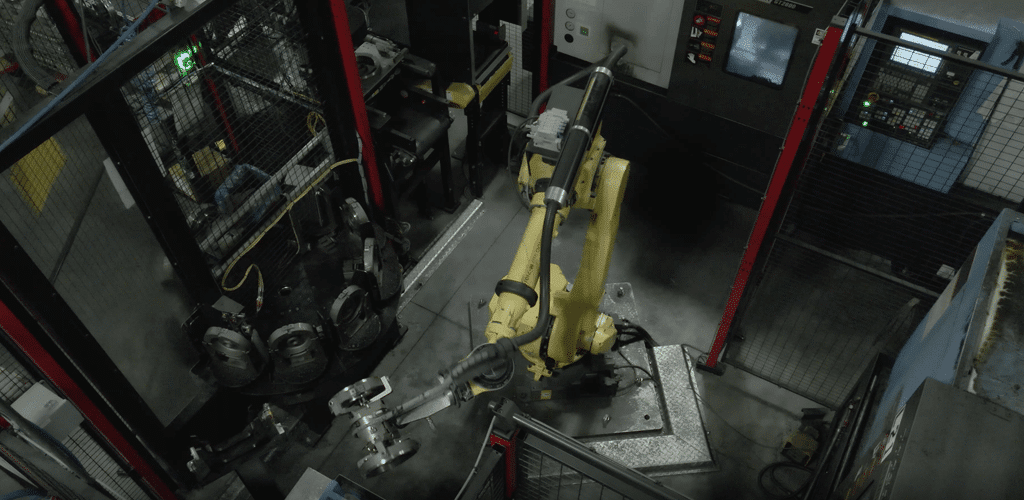

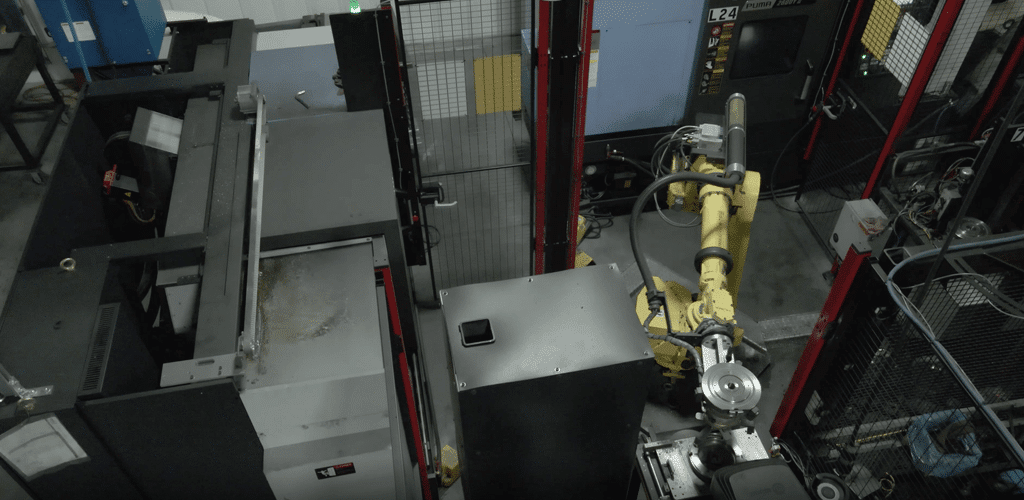

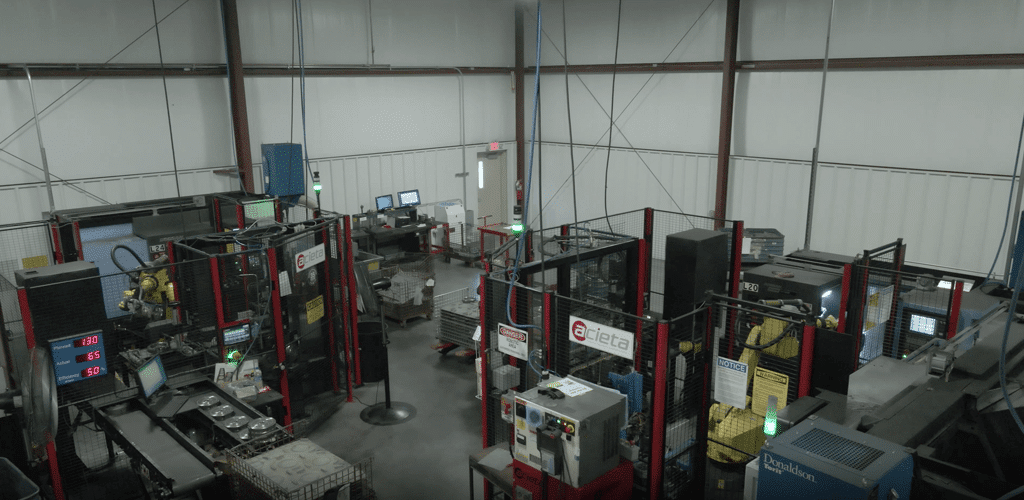

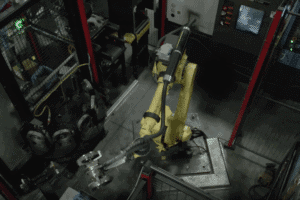

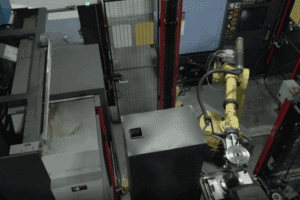

The following case study highlights our ability to provide solutions for complex machine engineering and integration challenges. By reengineering a machining cell and integrating automatic and robotic tending capabilities, we improved operations and, consequently, increased operational savings for the customer.

The Problem

When our customer’s orders started increasing, we had to find a way to keep up and deliver on time. We were experiencing increased volumes with a decreasing labor pool due to finding qualified personnel to operate the machining cells as engineered. Our goal was to reduce the gap between what our equipment was capable of and what the operators could achieve. By implementing robotics into this previously established machining process, we were able to create a more ergonomically friendly operation for our machine operators while increasing parts produced per hour.

Due to our previous performance record and turnkey capabilities (including machining and assembly), the customer knew they could rely on us to get the job done. While integrating the robotic technology, machine tools, and custom-built equipment would be difficult, our engineering and integration team was well-equipped to design, develop, and deliver a system that met all of the customer’s needs.