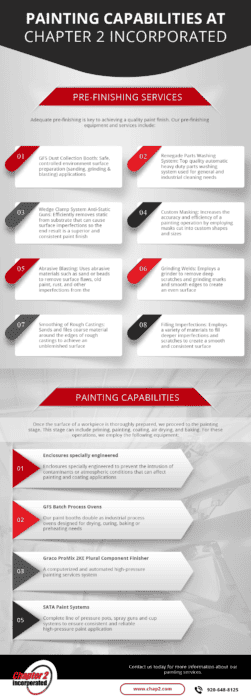

Established in 1973, Chapter 2 Incorporated began as a tool and die shop for manufacturing companies. Since then, we expanded our services to include a broad selection of contract manufacturing capabilities, including painting. Armed with a 14,000 square foot wet painting facility featuring state-of-the-art painting and finishing equipment, our team paints and finishes a wide range of materials in medium to large sizes for a diverse set of industrial applications.

We will pre-finish, prime, coat, air dry and bake any fiberglass, steel, aluminum, or plastic component up to 40 ft. long, 10 ft. wide and 9 ft. tall. Pre-finishing capabilities include custom masking, abrasive blasting, grinding welds, smoothing off rough castings and filling imperfections. Primers include two component primers and urethane primers. Coating includes top coat, urethane, enamel, carc, and waterborne coating.

Additional services include a wide range of testing capabilities, wet sanding and buffing (class A finish), custom packaging, shipping, and custom assembly. For more information, please see below.