Need Custom Workholding Solutions? Come to Chapter 2 First!

Do you need a partner that can provide the right workholding solutions to improve your productivity, precision and throughput? Do you have a specific production machining project in mind? Perhaps you need us to come up with a solution to your manufacturing challenges. At Chapter 2 Incorporated, we’ll work with your team to pinpoint the problem and brainstorm solutions. Whether you need simple fixture or have more complex production machining projects, our engineers are ready to help with the following custom workholding solutions:

Leak test fixtures

Leak testing is an inspection procedure that is used to assess whether a part or system is functioning within an allowable leak limit by measuring the amount of pressure that is lost over a given period of time. Liquid or gas held within a part will leak out if there is a flaw such as a hole or a crack.

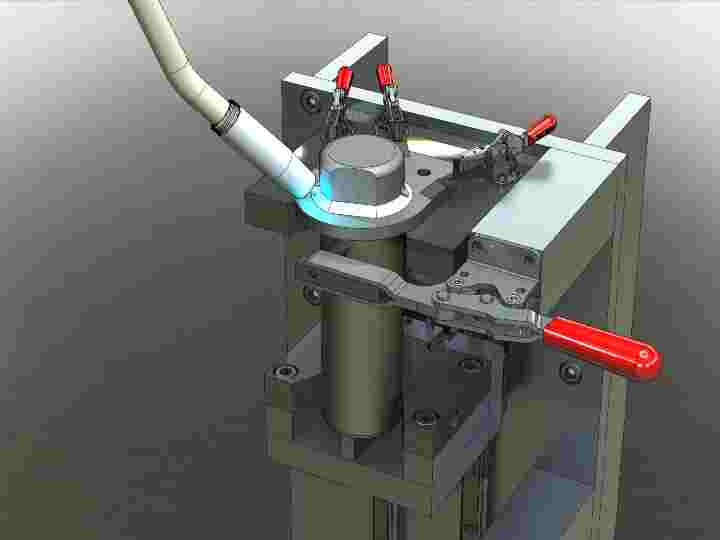

Welding fixtures

Weld fixtures hold parts with manual or pneumatic clamps in such a way so that they can be tacked or welded together manually or robotically.

Assembly fixtures

Assembly fixtures orientate pieces of an assembly in such a way that they are easy to assemble and decrease the amount of time it takes to build the finished product. It is important to arrange the fixtures suitably to be compatible with the intended operating tools.

Broaching fixtures

Broach Fixtures secure parts in place so that a toothed tool can remove the required material.

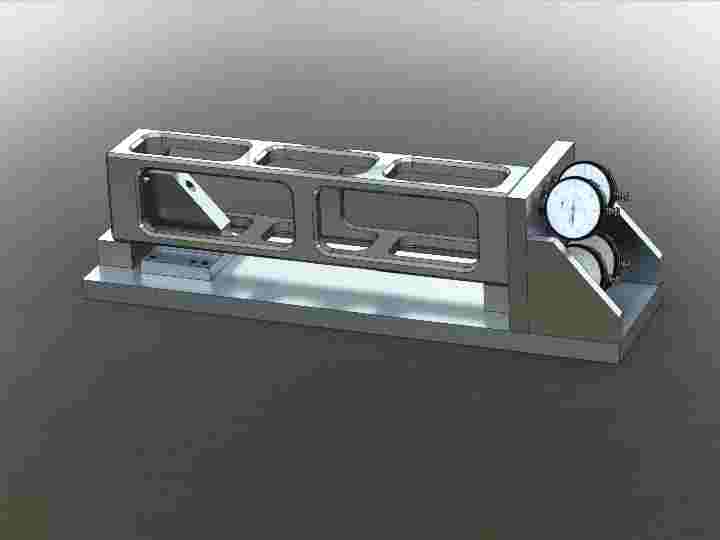

Inspection gauges

Inspection gages measure finished parts to a manufacturer specification. Master parts can be used to calibrate the equipment in order to ensure an accurate comparison.

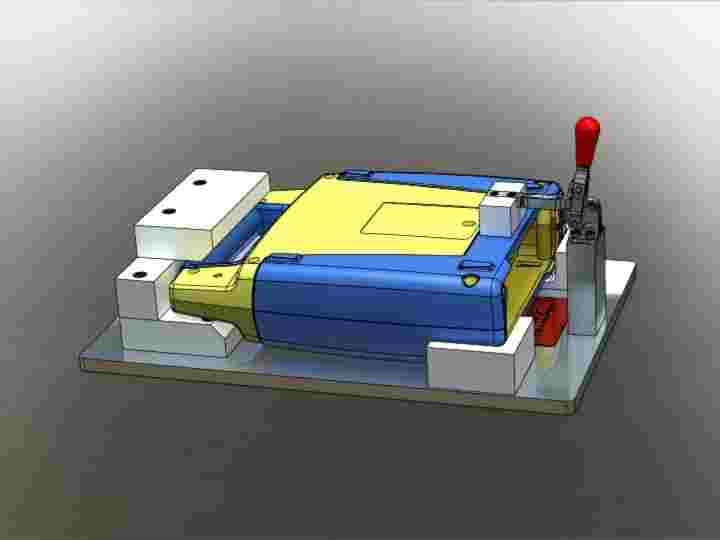

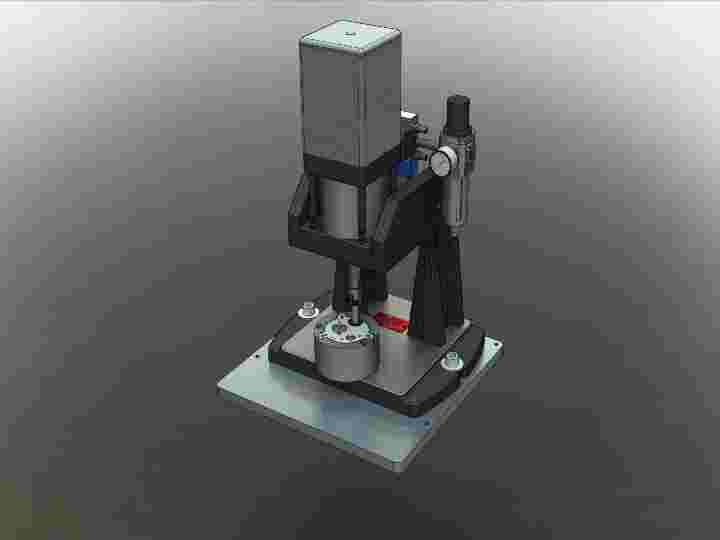

Pressing fixtures

Pressing fixtures are used to provide alignment and support to the circuit boards while inserting press fit connectors.

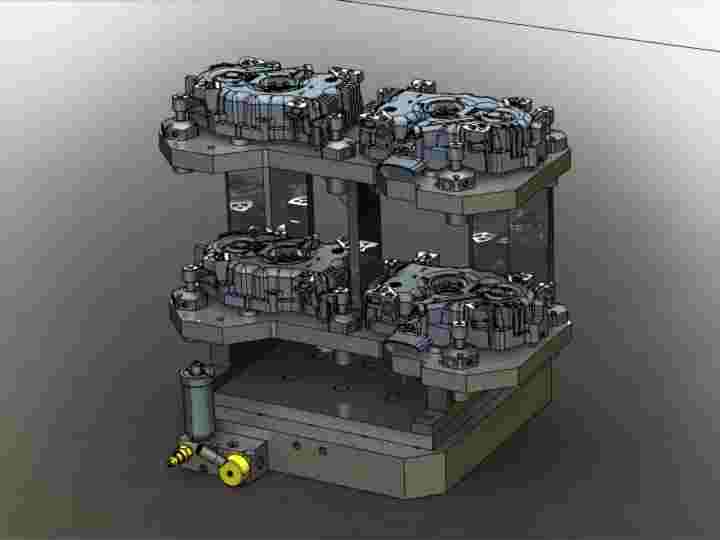

Machining fixtures

Machining fixtures orientate and secure parts with manual, pneumatic, or hydraulic clamps so that a machining operation can be completed without having a part move. This ensures that an accurate and precise part is created

Workholding Solutions That Work for You

For more than four decades, Chapter 2 has created jigs, fixtures, molds, dies, and machine tools. That includes numerous workholding solutions to meet your manufacturing needs. We also provide creative solutions for inspection gauges and automated equipment.

By providing workholding solutions for several manufacturing processes and industries, we have gained experience on what works and what doesn’t. So when overwhelming challenges arise, you can rely on us for workholding solutions that allow you to continue efficient production operations.

Chapter 2 has experienced Journeymen and a design process that involves our customers at every stage. They provide solutions for our customers’ workholding and fixture manufacturing requirements. Here are just a few of the advantages that set us apart:

- Dedicated team available for every project

- Highly skilled fixture technicians

- Comprehensive inspection and testing process with stringent approvals

- Documentation shipped with fixtures

- Secure file transfer capabilities

- And so much more!

Our Advanced Workholding Capabilities and Old-Fashioned Know-How For Quality

Using the most advanced technology, we are committed to affordable, precise workholding solutions that allow you to improve productivity, create high-quality parts, and deliver on time!

Here are just some of the industries we serve:

- Medical equipment

- Food packaging

- Construction

- Agriculture

- Military

- Automotive

- Lawn and garden

- Renewable energy

The Right Facilities for the Right Jobs

To better serve our clients, we have a large, working CNC machine shop. Additionally, you can see our full-service fabrication and weld shop in action. These dedicated facilities allow us to handle complex and simple orders.

We’re ISO 9001: 2015 Certified!

At Chapter 2, we are always on the lookout for ways to improve our knowledge and expertise. That includes certifications, training, and experimentation to offer our clients the most robust workholding solutions available.

- As part of this dedication to excellence, we have achieved ISO 9001:2015 certification for quality management.

- You’ll also find a well-equipped quality lab with two Zeiss Contura G2 coordinate measuring machines.

For more information about our services or capabilities, please request a quote today. You can also call us at 920-648-8125 with any questions you may have.