Our Services

Chapter 2, Inc. is a Contract Manufacturer specializing in

Our Portfolio

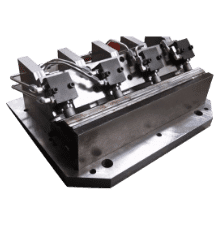

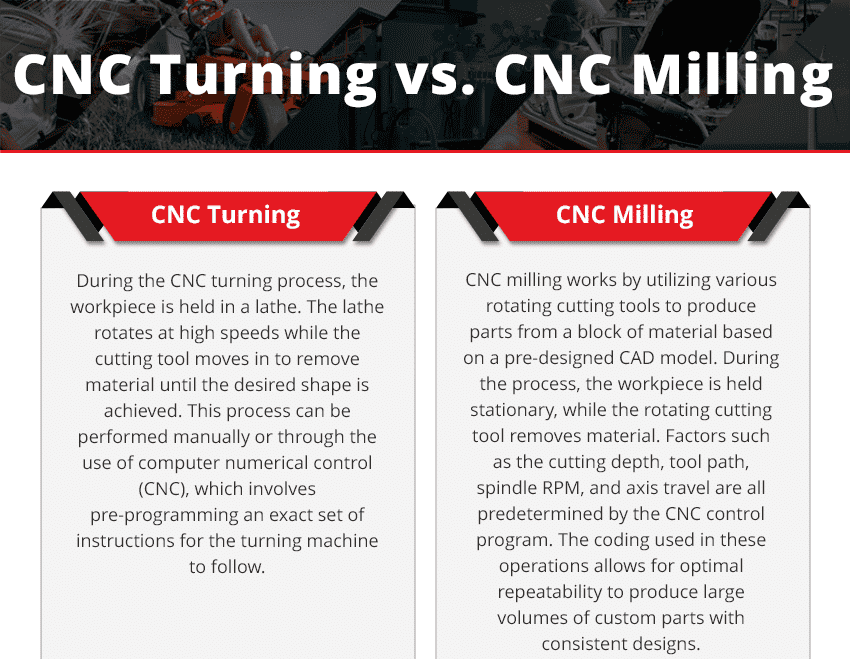

CNC Machining Automation Integration for the Power Equipment Industry

We reengineered a machining cell and integrated automatic and robotic tending capabilities to help our customer respond to an increase in orders.

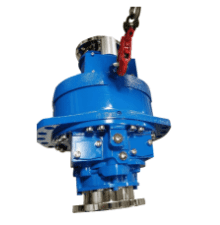

Gearbox Assembly

This international franchise approached us with a specific task in mind. They had a series of canopies and arches used on the façade of their restaurant that needed painting.

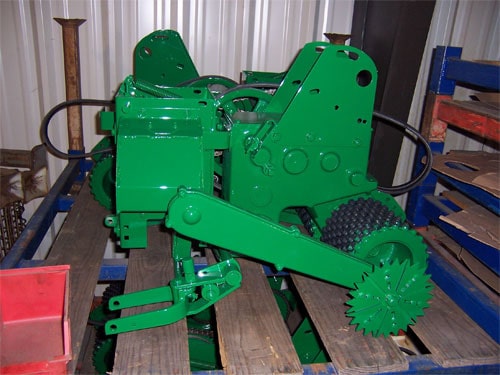

CNC Machining for the Lawn and Garden Equipment Industry

We have numerous projects in the lawn and garden industry, including complete DFM services. Some of our projects include: lawnmowers, sod cutters, tractors, and harvesting equipment.

CNC Machining for the Medical Device Industry

Our medical device projects include oxygen therapy components, lab equipment, testing equipment components, sensor housings, and hardware such as mounting plates and brackets.

CNC Machining for the Renewable Energy Industry

Our parts are used in various renewable energy projects. We serve multiple sectors of the renewable energy industry such as: wind power, solar power, and hydropower.

About Chapter 2, Inc.

One Stop Shop: At Chapter 2, Inc. we strive to become your One Stop Shop for all your manufacturing needs.

In-House Capabilities: Whether your part or project is manufactured completely in house or is sourced to one of our strategic partners you can rely on Chapter 2’s technical knowledge and project management skills to assure you that you’ll receive your product on time, in spec, and within budget.

Quality: Chapter 2, Inc. is an ISO 9001 Certified Business