Chapter 2 Invests in Precision: Meet Our New Horizontal Machining Center

Quick Summary: Chapter 2 upgraded its capabilities with a new DN Solutions NHP 5000 Horizontal Machining Center. This high-precision machine features a 15,000 rpm spindle, 500 kg pallet capacity, and a 120-tool changer, reflecting a commitment to superior quality and efficiency. The upgrade will directly lead to drastically reduced cycle times, higher throughput, and improved, repeatable precision on both complex, tight-tolerance parts and heavier workpieces, ensuring faster turnaround and greater flexibility for all client projects.

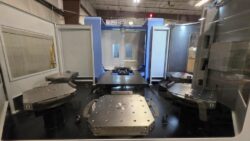

We’ve added a DN Solutions NHP 5000 Horizontal Machining Center to our shop floor. This upgrade reflects our commitment to enhancing productivity, precision, and flexibility. The NHP 5000 — equipped with a rotary pallet system (RPS) and a 120-station automatic tool changer (ATC) — brings significant capabilities to our machining operations.

Why We Chose the NHP 5000

- The NHP 5000 offers a spindle speed of 15,000 rpm, providing high cutting velocity suitable for aluminum, steel, and other demanding materials.

- It supports a workpiece load up to 500 kg on its pallet — ideal for heavy-duty parts or larger workpieces.

- The machine features high-precision linear guideways (roller-type LM guides for all axes), significantly reducing vibration and improving positional accuracy over traditional ball-bearing or slide ways.

- Its compact footprint and rigid bed structure make it an efficient addition — balancing power and space economy.

- These characteristics align with our focus on tight tolerances, reliable throughput, and consistent quality across varied part geometries.

Key Technical Specs & What They Mean for Our Work

15,000 rpm

Benefits: High-speed machining — faster cycle times on light and medium-duty parts.

500 kg workpiece weight, 500 × 500 mm pallet size

Benefits: Ability to work larger or heavier components without compromising rigidity.

X: 730 mm, Y: 730 mm, Z: 880 mm

Benefits: Generous working envelope for complex geometries and larger workpieces.

120-position (drum-style servo ATC)

Benefits: Extended machining cycles with fewer stoppages for tool changes — ideal for long runs or multi-step operations.

Rotary pallet system (RPS) + pallet changer, fast tool change, ready for automated workflows

Benefits: Significantly reduced non-cutting time, enabling leaner workflow and better uptime.

Expected Impact on Production & Quality

The NHP 5000 will directly contribute to:

- Reduced cycle times — Faster spindle speed, efficient tool changes and pallet swaps allow shorter lead times per part.

- Higher throughput — Less downtime between setups, enabling longer uninterrupted runs.

- Improved precision and repeatability — The rigid bed, roller guides, and stable spindle reduce vibration and thermal distortion, key for parts requiring tight tolerances.

- Flexibility — Large travel ranges and substantial tool capacity support a wide variety of part types and sizes, from small precision components to heavier, bulky parts.

These improvements help us meet growing demand for complex machined parts — all while maintaining the quality and consistency Chapter 2 is known for.

How This Benefits Our Clients & What It Means for Future Projects

- For prototype work or short-run parts, quicker setup and changeovers mean shorter lead times and faster turnaround.

- For long-run or multi-operation parts, the high tool capacity and pallet automation reduce labor dependency and lower the chance of human error.

- For large or heavy components, the 500 kg pallet capacity and generous travel envelope ensure we can reliably machine parts that previously required outsourcing.

- For clients needing tight tolerances or intricate geometries, the advanced rigidity and precision of the NHP 5000 offer consistent, repeatable results — aligning with industry best practices for quality control (e.g., ISO-based machining standards).

What’s Next: Integration into Our Workflow

We are currently calibrating the NHP 5000 and integrating it into our machining layout. During this phase, we will:

- Validate machine geometry and perform test cuts to verify tolerances and repeatability under load.

- Establish standard operating procedures (SOPs) for tool library setup, coolant & chip-evacuation cycles, and pallet handling workflows.

- Train CNC operators and setup personnel on efficient use of the 120-station ATC and rotary pallet system to maximize uptime.

Once we’ve completed initial validation, we plan to migrate select recurring jobs onto the NHP 5000 — prioritizing those that benefit most from automation, tight tolerances, or heavy workpieces.

We believe the addition of the NHP 5000 significantly enhances our machining capacity and flexibility — enabling Chapter 2 to take on more challenging jobs with improved efficiency and consistency. We look forward to putting this machine to work and delivering even greater value to our customers.

Contact us today to discuss how the NHP 5000 can deliver quality components for your project.