Latest Posts

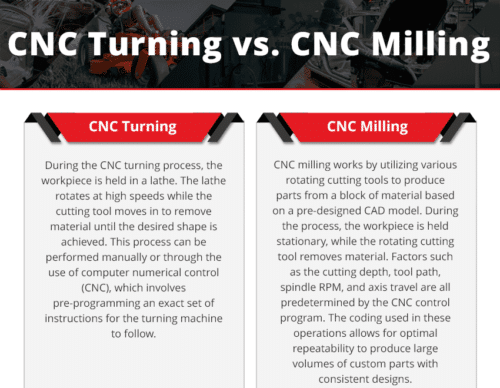

CNC Turning vs. CNC Milling

Machining is a type of subtractive manufacturing process that shapes materials into the desired product. Two main types of machining include CNC turning and CNC milling. During CNC turning, the cutting tool remains stationary while the material is rotated at a specific speed to create the exact shape. CNC milling, on the other hand, involves […]

Kali Garman added to Legendary Lake Mills Board.

Chapter 2, Inc, is proud to have our own Kali Garman as one of the Legendary Lake Mills Board Members.

What Is Design for Manufacturing?

Design for manufacturing (DFM) is a process that entails designing components, parts, or products to optimize the manufacturing process used to produce them. Ultimately, DFM helps maximize the efficiency and cost-effectiveness of manufacturing processes through optimized product designs that address any potential discrepancies or mistakes. People may also refer to DFM as design for manufacturing […]

Guide to Weld Types

What Is The Welding Process? Welding is the process of joining two surfaces together by applying heat, pressure, or a combination of both. The types of welds used to create the weld joint can be categorized into various types, which are largely defined by their cross-sectional shape and the methods used to produce them. Understanding […]

Chapter 2 is Committed to Keeping COVID Out

Chapter 2 is dedicated to #keepcovidout a local community initiative. Many precautionary measures have been put into place such as temperature checks, required face masks, and hand sanitizer located at numerous locations throughout the facility. Meetings have been relocated to different/ larger locations and maximum capacities have been put on many conference rooms and enclosed […]

Donation Drop off at The Ronald McDonald House- Madison, WI

What a beautiful day to do a beautiful deed! Some of the Chapter 2 Crew made their way to Ronald McDonald House Charities of Madison to drop off $500 worth of gift cards for surrounding restaurants that will be given to the families staying at the house while their children are being treated at the […]

Chapter 2, Inc. Donates to Local EMS

Chapter 2, Inc. is very excited to help the Lake Mills EMS purchase their first nitrous oxide tank to be used on their ambulances. The nitrous is used for immediate pain relief in place of opioids. If opioids are used in transit to the hospital, the patient cannot receive the necessary medical attention until the […]

Wisconsin Manufacturer of the Year Award Nomination

Chapter 2 is excited about their WIMOTY Award nomination and cant wait to attend the banquet on Feb 20th, 2020 among many other great manufacturers in the state. Manufacturing is an important industry in Wisconsin and this event is a great opportunity for manufacturers to get together and celebrate their successes and growth.

Congratulations on 25 years to Todd Schmidt

Chapter 2 would like to send a special Congratulations to Todd Schmidt, maintenance technician, on 25 years with the company! Todd has been a vital asset to the company’s successes, which includes fixing just about everything within the shop at least once and has never complained about the things he’s had to fix twice. Chapter […]

Robotic Machining and Automation

Chapter 2 has purchased their 2nd FANUC Robot paired with two new Doosan turning machines to add to their ever growing capacity! The robot tending operations aid in increased efficiencies and improve upon repeat-ability.